|

VIVAS Co. manager@vivas.com.ua | Odesa Ukraine +380 487001892 |

|

|---|---|---|---|

| VEGETABLE OIL PROCESSING EQUIPMENT | |||

| complete set of oil expeller | complete set of oil refining unit | industrial complete plants | |

| Complete set of oil expeller | |||

|

|

|

|

|

| MODEL | DL5 | DL150 | DL250 | DL400 |

| Capacity * kg/hour on raw material | 50 | 150 | 250 | 400 |

| Oil expeller : | ||||

| type | 95-А | 95 | 95х2pcs | 200-3A |

| power kW. | 5.5 | 7 | 7.5х2pcs | 22 |

| Feed screw conveyor, kW ( 4m high) with inlet hopper | 2.2 | 2.2 | 3 | 3 |

| Distribution screw conveyor, kW (2m long) | 0.55 | 0.55 | 0.75 | 0.75 |

| Filter press | 31 x 31 cm x 14 frames | 31 x 31 cm x 14 frames | 65 x 65 cm x 24 frames | 65 x 65 cm x 24 frames |

| Oil pump, kW. | 1.1 | 1.1 | 2.2 | 2.2 |

| Roast Kettle, kW Rotating barrel type.Fuel with gas or diesel | 0,75х2pcs | 1,1х2pcs | 1,5х2pcs | 2,2х2pcs |

| Dimensions, mm | 500х1200 | 700х1200 | 900х1200 | 1100х1200 |

| Crude oil tank & clean oil tank | stainless steel | stainless steel | stainless steel | stainless steel |

| Electric control panel | Incl. AMP&Volt meter, temperarture indicator, control for all equipments | |||

| Wear & tear spare parts | Incl.V-belts, oil rings, worm, sleeve, filter closs etc. | |||

| Oil residue of Cake ,% * | 5-8 | 5-8 | 5-8 | 5-8 |

| Oil content ,%* | 48 | 48 | 48 | 48 |

| Crude oil output kg * | 22 | 62 | 103 | 164 |

| Delivery FOB Shanghai, days | 30 | 30 | 30 | 30 |

| Delivery in | one 20' container | one 20' container | one 20' container | one 20' container |

| * It is calculated on sunflower seeds |

| Table of results of different seeds processing |

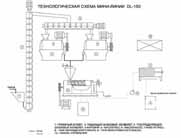

Flow chart for DL150 |

|

||||||||||||||||||||||||||||

| This high effective and reliable oil expeller set is an ideal low cost equipment for small enterprises who planned to start their own production of vegetable oil. | |||||||||||||||||||||||||||||

| Complete set of vegetable oil refining unit | |||||||||||||||||||||||||||||

|

This complete set high quality cook oil

refining unit applies to various kinds of edible oil refining including de-gumming, de-acidification, bleaching and deodorization. The

finished oil reaches national standard of high quality cook oil (in case of

winterization). This unit requires small investment and obtains instant effect. It is more

suitable for small scale oil mills and private entrepreneur and is reccomended to use

togetther with complete set of oil expeller Refining unit has 10 models with capacity from 300kgs to 5000kgs per day. Please read more... |

||||||||||||||||||||||||||||

Industrial vegetable oil treatment equipment |

|

|

|

|

|

| 100Mt/day Sunflower Seeds Preatreatment and Pressing Station |

100Mt/day Sunflower Seeds Preatreatment and Pressing Station equipment list. Click here to see flow chart |

|||||

| STEAM CONSUMPTION:1.5T/H TOTAL POWER OF INSTALLATION: 298,7KW Construction Area: 40X10M2 Height: 4.5X2=9M (Part area require 4.5X3=12M Height) |

|||||

| Dwg. No. | Description | model | Power | Q-ty | Remarks |

| kW | PCS | Material | |||

| P-01 | Gate Feed Hopper | WLQ-80 | 3 | 1 | Q235-A |

| P-02 | Aspirating Collector | YLQ-15 | 1 | Q235-A | |

| P-03 | Discharger | XGQ-50 | 2,2 | 1 | Q235-A |

| P-04 | Magnetic Separator | TCXT-30 | 1 | SUS 304 | |

| P-05 | Dentate Roller Huller | PSG-215X800 | 22 | 1 | Q235-A |

| Р-06 | Bucket Elevator | TDTG-36/23 | 1,5 | 1 | Q235-A |

| P-07 | Kernel Husk Separator | JFS-60 | 5,5 | 1 | Q235-A |

| Р-08 | Flake Mill | YP80X100 | 60 | 1 | Q235-A |

| P-09 | Scraper Conveyer | GSL-20 | 3 | 1 | Q235-A |

| P-10 | Cooker Kettle | ZCL-24X5 | 47 | 1 | Q235-A |

| P-11 | Scraper Conveyer | GSL-25 | 3 | 1 | Q235-A |

| P-12 | Oil Press for Once-pressing or Oil Press for Pre-pressing* |

Z-390 | 110 | 1 | Q235-A |

| Р-13 | Cake Scraper Conveyor | GSL-20 | 3 | 1 | Q235-A |

| P-14 | Crude Oil Tank with Dreg Remover | YGY-150х150 | 1.5 | 1 | Q235-A |

| P-15 | Crude Oil Pump | NJB-1 1/2" | 1,1 | 1 | Q235-A |

| P-16 | Oil Defecation Tank | CYX-3 | 1,5 | 1 | Q235-A |

| Р-17 | Oil Intermediate Tank | YGY-100 | 1 | Q235-A | |

| Р-18 | Intermediate Scale | 1 | Q235-A | ||

| P-19 | Clean Oil Tank | YGY-150х150 | 1 | Q235-A | |

| P-20 | Clean Oil Pump | 2CY-5/3.3 | 2,2 | 1 | Q235-A |

| P-21 | Pulse Dust Remover | TBLMZ 36A | 1,1 | 1 | Q235-A |

| Р-22 | Elevating Aspirator | 9-19-6.3A | 15 | 1 | Q235-A |

| P-23 | Steam Divider | FPW-30 | 1 | Q235-A | |

| Р-24 | Husk Discharger | o900 | 1 | Q235-A | |

| P-25 | Pulse Dust Remover | TBLMZ 36A | 1,1 | 1 | Q235-A |

| Р-26 | Conveying Aspirator | 9-19-6.3A | 15 | 1 | Q235-A |

| Total | 298,7 | 26 | |||

| * Once pressing is

with less oil residue in cakes and may without solvent extraction later. Pre-pressing is

with high oil residue in cakes for solvent extraction later. Manpower Configuration for Oil Plant per shift |

|||||

| Working Section or Station | Subsection | Qty. |

| Pretreatment | 2 | |

| Pressing | Expeller | 1 |

| Cooking Kettle | 1 | |

| Solvent Extraction | Extractor | 1 |

| Roaster | 1 | |

| Evaporator & Condenser | 1 | |

| Coordinator | 1 | |

| Refining | Neutralization | 1 |

| Winterization | 1 | |

| Bleaching | 1 | |

| Deodorization | 1 | |

| Mechanic | 1 | |

| Electrician | 1 | |

| Laboratory technician | 1 |

| Complete corn processing plant with capacity of 100MT/day (incl. decortication, grinding, corn embrio oil pressing, corn embrio oil extraction stations, complete corn oil refining and winterization unit) |

VIVAS Co. |